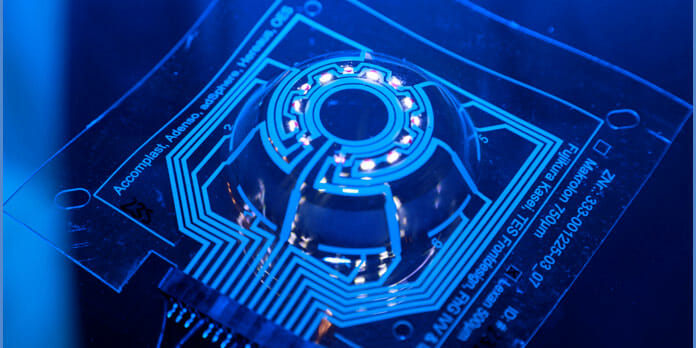

ORIGAMI Project yields novel touch wheel from high-precision 3D forming

A pioneering touch slider enabled by multiple layers of printed electronics and combined with innovative heating, thermoforming and injection molding technologies, was developed in the publicly-funded Innovations with Organic 3D Electronics (ORIGAMI) project, which brings together various German and Japanese technology companies and institutes. The demonstrator is equipped with 14 LEDs, has a drawing depth of 10mm, and a touch functionality. This engineering feat enables the fast sheet-to-sheet production of injection-molded 3D electronic devices, reducing the necessary productions steps and overall weight of the finished devices. This achievement in printed electronics is expected to find its way to automotive interiors, white goods, large electronic appliances, and medical equipment, among others.

The ORIGAMI project is funded by the German Federal Ministry of Education and Research and coordinated by Organic Electronics Saxony (OES). Dr Jonas Jung, project leader at OES, said: ‘This exciting demonstrator is a great result of the ORIGAMI project, showing the innovative strength of the longstanding German-Japanese collaboration. By utilizing novel production technologies the demonstrator showcases new application possibilities for printed electronics.’

Technological collaboration

Heraeus produced Clevios conductive polymer pastes, which are PEDOT:PSS-based formulations for screen printing. They are used to print transparent conductive electrodes, used in many devices and new technology applications such as capacitive touch sensors. They can be thermoformed into three dimensional shapes and are flexible, transparent and highly conductive. Within the ORIGAMI project, Heraeus could further optimize the Clevios paste to enable stretching the transparent electrodes by more than 100%.

Fujikura Kasei provided two DOTITE inks – an electrically conductive ink and an electrically insulating ink – which are used to screen-print thermoformable multi-layer conductive traces on polycarbonate. They are designed for a high degree of deformation when thermoformed with minimal loss of conductivity. They are also able to withstand the injection molding process, allowing them to be used to create exciting in-mold, printed electronic devices.

TES Frontdesign printed the touch sensor foils and equipped the LEDs. The challenge they faced was to print with the new developed silver and isolation inks onto a stretchable foil. TES Frontdesign developed, together with the Fraunhofer Institutes and adSphere, different sensor and connection line designs to use the stretchable properties of the inks for the sensor foils. An additional challenge was the gluing of the LEDs. The touch foils have touch sensor areas in a form of a ring. TES Frontdesign developed hard- and software to show the functionality of the touch sensor areas on the computer screen.

Fraunhofer IVV developed the geometry of the demonstrator. Care was taken that no critical elongation maxima are existing. Furthermore, it was up to now not possible to form parts when the electrical components are mounted around the forming area. A new technology has been developed for this purpose, which allows components to be taken into account during forming. For successful forming, material characterizations were also conducted in order to use the optimum materials and forming parameters for the forming process. Nevertheless, harsh process conditions of thermoforming and subsequent injection overmolding require reliable mounting technologies with sufficient bond strength.

Fraunhofer IZM developed fully in-line compatible SMT processes based on thermoplastic substrates, printing and adhesive bonding. Accelerated ageing tests of overmolded test coupons, including a variety of different circuit materials and components (stretchable Ag-paste, conductive polymers, 0201-, 0402-, 0603-, 1206-, VSOP8-components) have validated reliable functionality within the chosen test environments (thermal cycling, thermal storage, temperature humidity).

To demonstrate new technologies and to present the new product and design options, Adenso implemented a demonstrator system with which these technologies were included in a roll-to-roll process. This enables the production of 3D electronics in a cost-effective process suitable for the masses. Through an extensive series of tests, Adenso has optimized the process in such a way that functional models with a molding depth of up to 14mm could be produced.

adSphere has redefined input devices: By reshaping directly from the substrate, operating elements can be made gap-free, hygienic and watertight. This replaces the conventional processes in which operating elements often consist of many individual components. Thanks to the capacitive touch surfaces and the slider elements, many functions can be combined into just one part in the future. The new input devices are therefore ideally suited for applications in medical technology, in the field of white goods or the automotive industry.

Accomplast, a plastics processor, used its technology for the overmolding. Sub-assemblies are now replaced by direct integration into individual plastic components through overmolding. The challenge was to achieve resistance of the printed electronics to the temperatures, pressures and sometimes abrasive effects of the plastic flowing into the printed structures and the applied electronic components. Narrow process windows in the injection process were indispensable. Due to the close cooperation between the producers of printed electronics and Accomplast as a plastics processor, the now-available demonstrators could be produced as representative results.

About the ORIGAMI Project

Launched in 2018 with funding from the German Federal Ministry of Education and Research, Innovations with Organic 3D Electronics (ORIGAMI) is dedicated to two challenges in the field of printed, flexible, organic electronics. Intelligent OLED-OPV based systems will make interactive advertising applications possible. For the development of the planned demonstrator the existing technologies must be further developed and combined. In a second development strand, electronically functionalized 2D films will be transformed into plastic 3D objects by a thermal forming process. At the end of the project it will be possible to produce simple demonstrators in a continuous process in a demonstration plant. A part of the technologies will be researched in cooperation with partners from England and the partner cluster in Yonezawa, Japan and coordinated by Organic Electronics Saxony (OES).

ORIGAMI Project yields novel touch wheel from high-precision 3D forming (Source: adSphere)

About the Partners

Accomplast GmbH

Accomplast GmbH has become firmly established as an important supplier to the automotive and electronic markets as a result of its focus on reliability, individuality, high quality and innovation. Accomplast offers a wide range of technologies are based around plastic injection moulding (1K/2K) and include state-of-the-art surface finishing and fully automatic assembly systems.

Adenso

Founded in 1989, Adenso today deals with the construction of modular robot platforms and automation solutions for the semiconductor industry, as well as roll-to-roll systems (R2R) for processing flexible materials for printed electronics and battery technologies.

adSphere

adSphere offers new and innovative technologies for sensors, functional layers, lamination technologies, substrate handling and assembly. The processes are scalable and are suitable for large-area and flexible electronics for production using the cost-effective roll-to-roll process.

Fraunhofer IVV

Fraunhofer IVV is a leading R&D institute in the area of process engineering and packaging. Commissioned by organizations in the private and public sectors, Fraunhofer IVV creates added value for its customers.

Fraunhofer IZM As part of the Fraunhofer-Gesellschaft, Fraunhofer IZM specializes in applied and industrial contract research. Fraunhofer IZM’s focus is on packaging technology and the integration of multifunctional electronics into systems. The institute has a staff of more than 430 and saw a turnover of 35,7 million euros in 2019, of which 41,8 percent was earned through contract research. Fraunhofer IZM has two sites in Germany. Apart from its headquarters near Berlin Mitte, the institute is also represented in Dresden and Cottbus, strategically important centers for electronic development and manufacturing.

Fujikura Kasei Co., Ltd.

Fujikura Kasei Co., Ltd. is a chemical materials manufacturer based in Tokyo, Japan, and the maker of DOTITE brand silver-based conductive pastes.

Heraeus

Heraeus, the technology group headquartered in Hanau, Germany, is a leading international family-owned portfolio company. The company’s roots go back to a family pharmacy started in 1660. Today, the Heraeus group includes businesses in the environmental, electronics, health and industrial applications sectors. Customers benefit from innovative technologies and solutions based on broad materials expertise and technological leadership.

In the 2019 financial year, Heraeus generated revenues of €22.4 billion with approximately 14,900 employees in 40 countries. Heraeus is now one of the top 10 family-owned companies in Germany and holds a leading position in its global markets.

Heraeus Epurio is the technology and market leader in essential materials for capacitor, display, and photoresist applications, producing Clevios, the pioneering standard for conductive polymers with over 30 years of demonstrated success; and ultra-pure specialty chemicals, which are a critical component in the semiconductor industry.

TES Frontdesign GmbH

TES Frontdesign GmbH is one of the leading providers of individual control systems in Germany. We realize customer-specific projects from the membrane keyboard to the complete operating system with housing, including the assembly of electronic units, especially for small and medium-sized lot-sizes. Our core competence is the complete production, our unique selling point is the great range of manufacturing steps at our single production site in Neuruppin, Germany.