adSphere makes ITO coating on UTG a standard process

ITO coating on rollable ultra-thin glass (UTG) with excellent properties

adSphere implements innovative transparent and conductive layer with excellent properties.

Our industrial partner Creavac developed the layer system specifically for use on glass substrates, on the basis of many years of experience and in numerous tests.

The significantly higher process temperatures that guarantee optimum values in terms of transparency and conductivity can be achieved only when using glass as the basic substrate – they can never be achieved on polymer films.

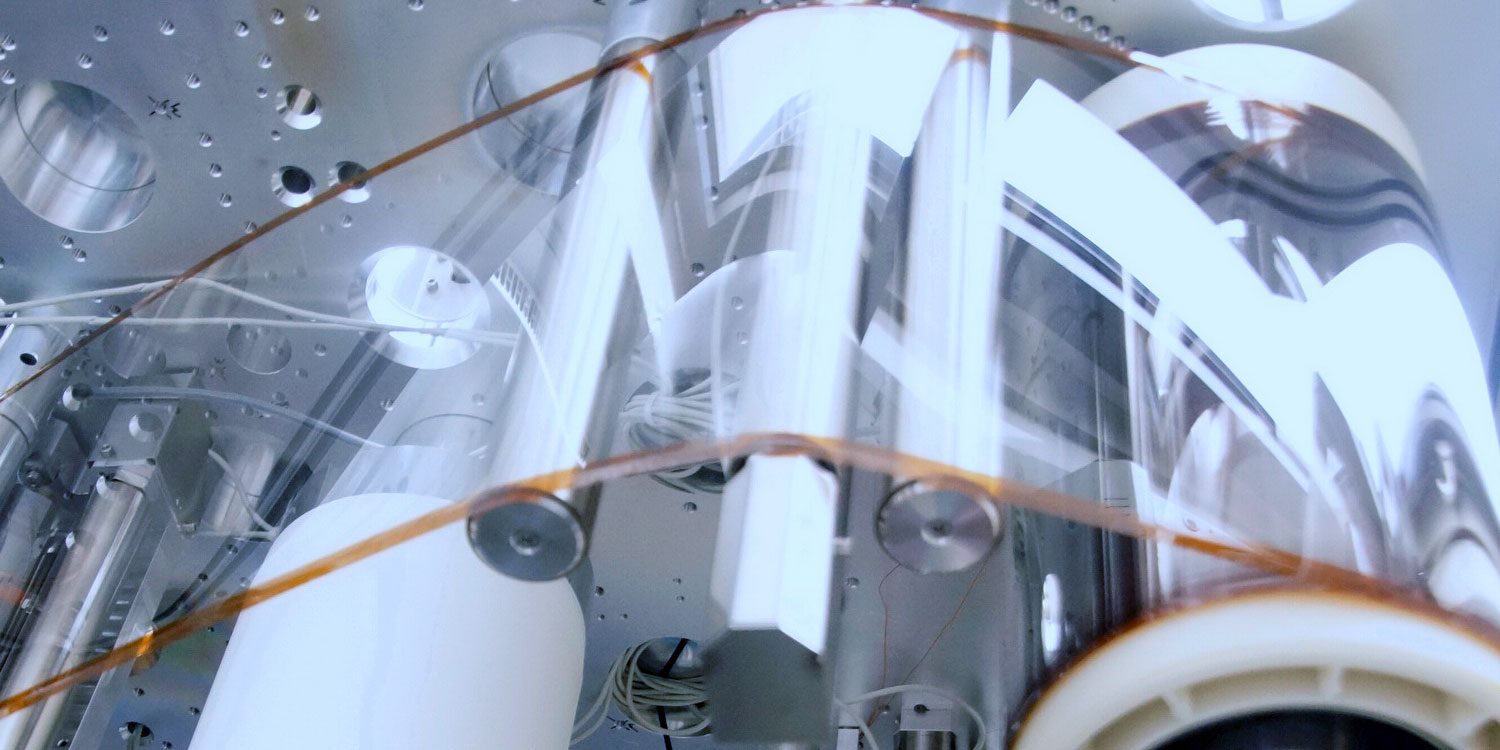

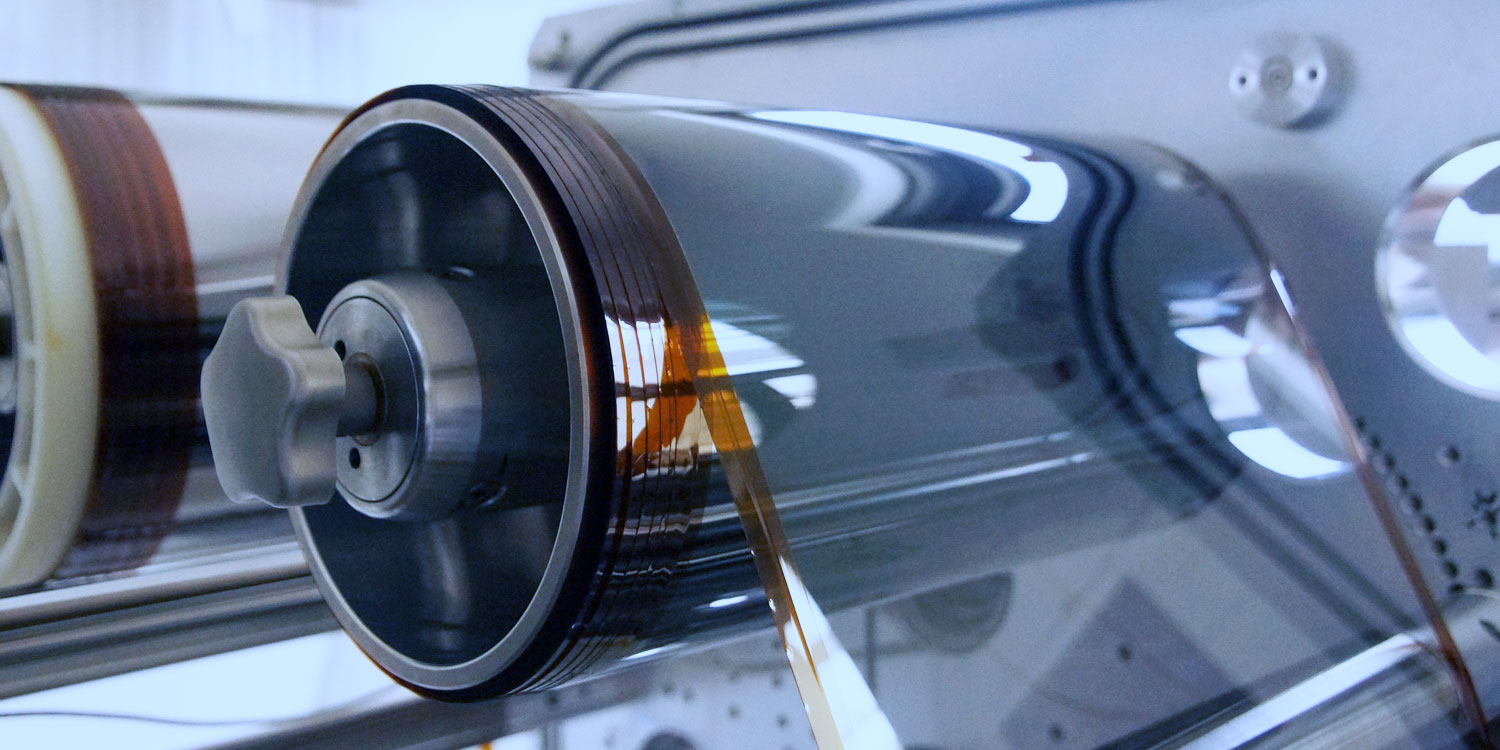

An ultra-thin glass customer substrate that was processed straight from the roll, blank and without a laminated support layer, was used here.

For reasons relating to physics, the layer, which is only a few nanometres thin, is processed in a clean high-vacuum environment.

With adSphere’s industrial partner Creavac, a job coater is now able to include such services as a standard process in its portfolio and offer them on the global market.

What are such transparent, conductive layers needed for?

One example of a field of application are organic materials like the ones used in organic light-emitting diodes (OLED) and organic photovoltaics (OPV). In combination with the glass as an ideal barrier, these layers can display the full range of their advantages over polymer films, which, in contrast to glass, are permeable to water vapour and therefore require barrier layers. Besides the cost factor, these barrier layers have so far proven to be the crucial weak point of electrodes on a polymer basis. In concrete terms, this means that the OLED/OPV have a near unlimited service life when using glass substrates; by contrast, in the case of polymer films that often have inadequate barrier layers, signs of degradation sometimes occur after a relatively short time of one year or even less …

Furthermore, such layers are indispensable for all types of touch sensors. Here too, we see the benefits of the direct combination with the glass of the end application in the form of better technical properties (scratch resistance, excellent optical properties, …) as well as additional cost savings due to the fact that polymer films and barrier layers are not needed.

Why is this step so important?

Our customers need solutions that are suitable for the industry. It is therefore important that adSphere.solutions takes this step to demonstrate that the technology transfer from basic research to the producing industry has been successful.

How does adSphere use this technology?

This step comes at an ideal time, as adSphere is in an advance development phase for large-scale, glass-based sensors. This technology can thus be incorporated directly into the development of the adjoining technologies and planned products.

Which further steps is adSphere planning to take in this area?

Although adSphere has taken a big step forward, the substrate variants differ strongly in terms of thickness and condition on delivery. This is due to the fact that there is no industrial standard to date. adSphere and its research and industrial partners are therefore currently working on extensive developments in order to cover this variety on a machine- and process-related level. Ideally, this will result in a new industrial standard for processing ultra-thin industrial glass (UTG), which will ensure safety and contribute to profitable use due to variant reduction.

adSphere contact and sensor systems expert:

Uwe Beier, CEO

Tel: +49 351 79 59 79 7-60

info@adsphere.solutions

adSphere industrial partners